Craftsmanship tradition since 1887

When you enter the BRAUN BÜFFEL leather factory, you can see why the buffalo has become the trademark for high-quality leather accessories around the world: the earthy scent of finely tanned leather is in the air. The factory was opened in 1887 as a saddlery and upholstery business in Kirn. Even more than 135 years later, leather goods are lovingly handcrafted by our fine leather craftsmen in Kirn and, since 2022, also in Offenbach.

What is a ManuFaktur?

The term "manufacturing" is often heard - it is not a foreign word. But what exactly is behind the term and what is done in a manufacturing facility? Are there different manufacturing styles and how does BRAUN BÜFFEL actually work? We would like to answer all of these questions for you today, in this article. BRAUN BÜFFEL tradition is manufacturing work - with attention to detail. The highest quality standards made by hand.

The heyday of the original and initial manufactories was in the years 1780-1820. The manufactory is described as a "large-scale goods production organization". Replaced by the factory, BRAUN BÜFFEL remains with the classic type of manufactory and thereby revives the craft. In order to work more efficiently, machines were partially integrated, but the most important work is carried out by the production and its employees themselves. No machine recognizes the character of unique leather.

The origin of the term can be found in old Latin. "Manus" means the hand. "Factura" means "to make" in German. The combination of the two Latin terms means "to make by hand". In the factory, work is carried out by hand and products are manufactured to a high quality.

Today, the factory stands between a modern, contemporary factory and the traditional craftsmanship of the time, in which there was not a single machine to facilitate work.

Manufacturing plays a particularly important role in the world of leather. Leather goods require a great deal of attention and experienced leather craftsmen so that the material can be processed optimally.

The fine leather maker impresses with his experience and know-how. The craft profession has become very rare over time, as the trend has shifted towards cheap production with less high-quality leather goods. BRAUN BÜFFEL, on the other hand, has remained true to its line and still impresses with the art and profession of the fine leather maker. This is also a reason for the search for new talent. The profession of fine leather maker needs new talent. Due to a change in values among Generation Z, which consumes more thoughtfully and consciously, high-quality handcraft is once again gaining importance and lending the profession of fine leather maker charm and importance.

Where are the BRAUN BÜFFEL factories?

The Braun family took the first steps toward becoming a manufacturing company over 138 years ago. BRAUN BÜFFEL and its first manufactory began in the center of Kirn, a small, manageable town in Rhineland-Palatinate, located between Frankfurt and Saarbrücken. A few years later, the company grew, and BRAUN BÜFFEL reorganized itself in the Kirn industrial park. The current master fine leather maker has been with BRAUN BÜFFEL since his apprenticeship, which he successfully completed at a young age. For this reason, it is particularly important to find new talent so that the years of tradition and experience can be passed on to motivated future fine leather makers.

Since the beginning of 2022, there has been another manufactory that exclusively produces BRAUN BÜFFEL products. The Offenbach-based manufactory, with two fine leather craftsmen and several production employees, lives and breathes the BRAUN BÜFFEL culture and, together with Kirn, creates special, one-of-a-kind leather pieces. Working hand in hand allows the manufactories to easily exchange ideas, and the individual strengths of each employee can be utilized to their full potential. The exciting and varied work of the fine leather craftsman will receive support! In fall 2022, there will be more fine leather craftsman apprentices. The tradition will continue, and BRAUN BÜFFEL is excited about new input and the future journey of the manufactories. Together, we stand for quality and craftsmanship.

LOYAL PARTNER MANUFACTURERS

In addition to the German factories in Kirn and Offenbach, BRAUN BÜFFEL has also been working with excellent partner factories in Asia for decades. Long-standing partnerships and friendships characterize the leather goods value chain.

HANDMADE LEATHER GOODS

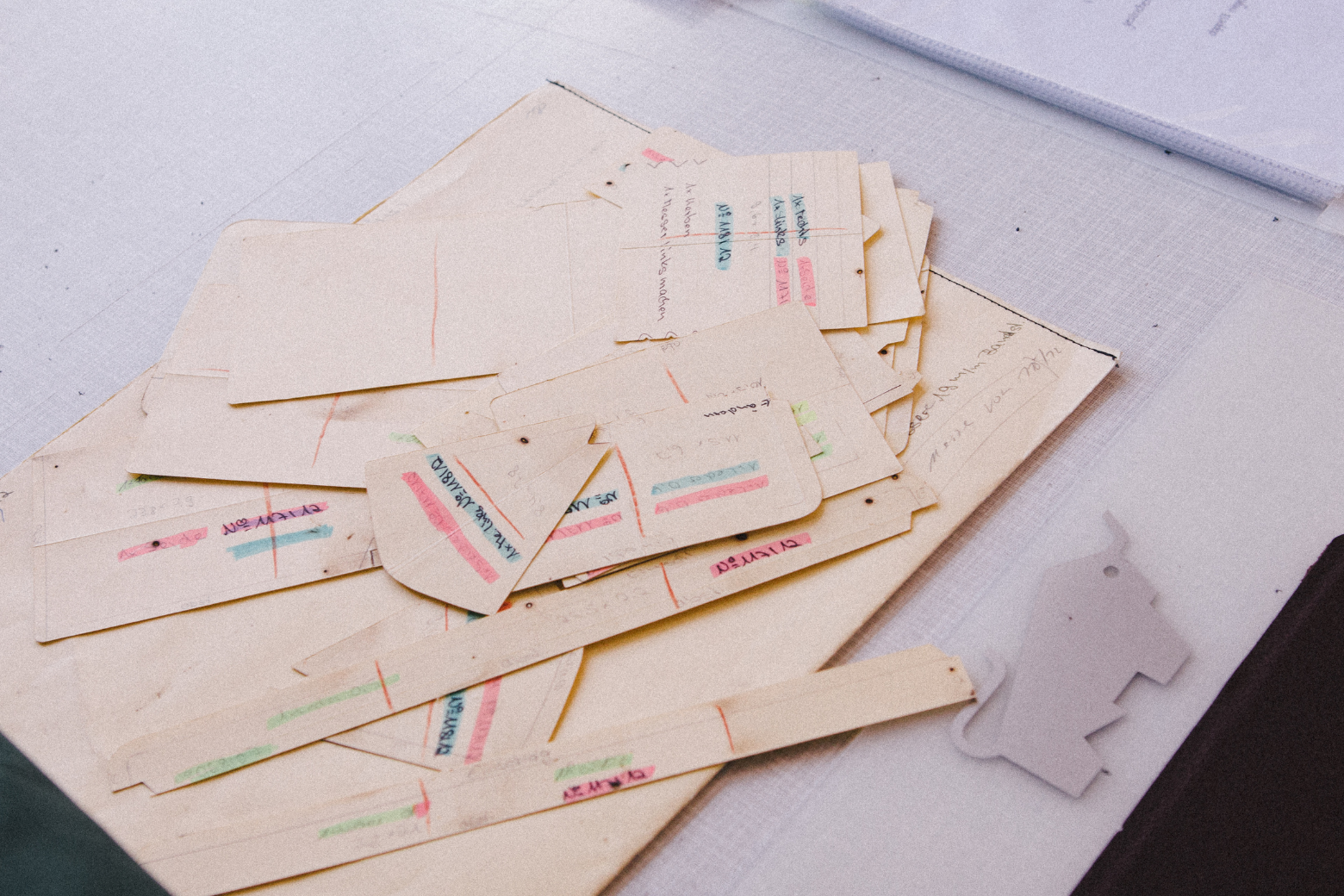

Fine leatherwork is a profession in which small decisions are often important, which can have a huge impact on the overall appearance of a leather product. Ideas, concepts and wishes are used to create patterns that are changed several times until the overall composition is right. Individual parts form a larger whole.

Leather is not a rigid material. Every leather is unique and therefore needs to be treated in a unique way. The implementation is free. The character of the leather needs to be taken into account - in a finished leather product, the leather should be shown at its best and strengthened. The fine leather maker recognizes these special characteristics and lets them shine with new splendor.

People are often unaware of how many individual parts their beloved wallet or bag consists of. A zipper here, a card compartment there - all of this is made by hand. The high quality of BRAUN BÜFFEL products is the result of skill, attention to detail and craftsmanship. For this reason, each product is unique and no one in the world can reproduce it 100%. The uniqueness is a plus point of manufacturing in a factory. In addition, personal wishes of the buyer can be taken into account. Due to smaller quantities, no mass production and handwork, it is possible to have the leather goods personalized for gifts or other occasions. Whether initials, whole sentences or individual symbols - the fine bag makers and production employees always strive to meet the buyers' requirements. The extent to which they can implement your wish often depends on the size of the leather goods. The quality of the leather also plays a major role.

Our fine leather craftsmen lovingly handcraft purses, wallets, business bags, handbags, luggage, backpacks, key and card cases as well as leather accessories for men and women from the current "Made in Germany" series . In addition, new prototypes are built and personalizations are created. Our fine leather craftsmen also provide a lifelong repair service with the utmost care.

The path from the paper pattern to the finished wallet is a lengthy process that passes through many critical and perfectionist eyes. Work steps with a scope of 50-60 are not uncommon. Would you like to find out more about the process of making a wallet or bag? Visit us in the "World of Leather" guide - you can expect exciting care tips and deep insights into traditional craftsmanship.

LEATHER CRAFTSMANSHIP AT ITS FINEST

We would be happy to give you an insight into our factory and the work steps of our specialists for high-quality leather processing.

MAKING A WALLET

Fine bag maker Manfred Goll makes a wallet. In these prototypes, everything is handmade, from the paper templates for the cuts to the processing of the leather.