Smooth, coarse, silky, rough: how leather looks and feels is largely influenced by the leather grain. But how are the different leather surfaces created and what is behind the word "leather grain"?

Roughly speaking, the term "grain" refers to the pattern on the surface of the leather. This differs in color, thickness and structure. The grain side is the so-called hair side of the original animal hide. In other words, the side on which the animal's fur grew. This means that all leather is naturally grained. However, the leather grain can also be changed through mechanical processing.

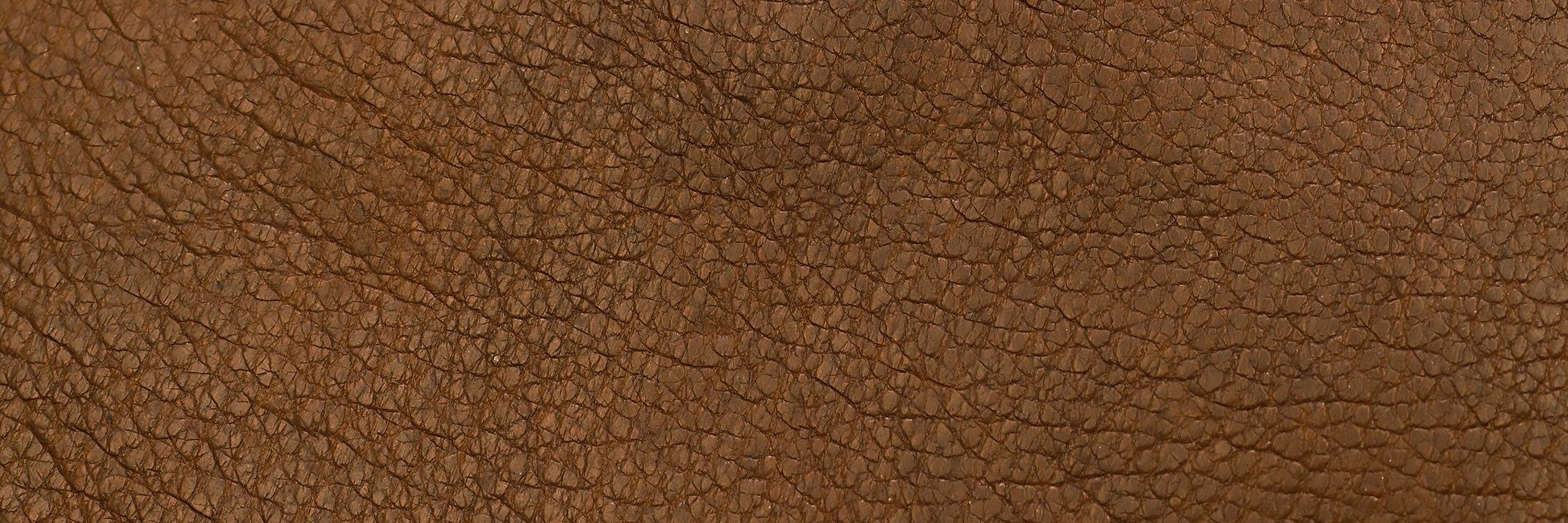

Each type of leather has a unique, characteristic grain pattern. The natural grain is created by the original surface texture of the leather. The grain pattern of the leather can be changed through embossing and dyeing, and split leather can also be given a grain through surface treatment. Here, a very thin film with a grain look is applied.

HOW IS THE LEATHER GRAIN CREATED?

The natural grain pattern differs depending on the origin of the leather. It therefore plays an important role whether the leather comes from a cow, buffalo, sheep or another animal. Each animal species has a characteristic skin structure that affects the grain of the leather. But it is not only the animal species that determines the look and feel of the grained leather. The climate, lifestyle, age and injuries of the animal also influence how the skin develops and what the later grain pattern of the leather will look like.

The grain pattern is also largely determined by the thickness of the hide. Thinner leather often has a finer grain, while thicker leather has a coarser structure.

In order to turn skin into leather, it goes through several stages in the tannery, known as tanning . These also determine what the leather will look like in the end.

THE THREE STATIONS OF A TANNARY

The Water Workshop

Here the animal skin is freed from hair, feces, meat residues and so on.

The Tannery

This is the essential step in leather production that turns organically perishable rawhide into leather.

The preparation

This is where the leather is dyed and milled. During milling, the leather is in a kind of large dryer. If the leather is milled for a short time, it becomes softer and retains the original grain pattern; if the leather is milled for a longer time, the grain pattern becomes coarser. Nevertheless, the leather grain remains natural. This means that the grain is evenly fine in the back area and coarser towards the belly. In order to achieve a uniform grain pattern, the grain pattern can also be embossed.

THE NATURAL LEATHER GRAIN

If the grain pattern of the leather remains largely natural, it is referred to as natural leather grain. Small irregularities, which can arise from different skin regions or injuries, give the genuine leather a unique appearance. The leather is often fine-grained on the back of the skin and becomes coarser towards the belly. The natural product leather makes each product unique. Imperfections are not just tolerated. An irregular grain pattern clearly shows that the leather is high-quality, natural genuine leather. For example, healed wounds, mosquito bites and wrinkles can be seen on the animal's skin and give the genuine leather a special character.

A NEW SCAR IMAGE

In order to achieve a very uniform grain pattern without irregularities, the surface of the leather can be embossed over the entire surface. In this way, for example, cowhide can be given the typical look of reptile leather. The result is the well-known crocodile or snake embossing. Here, the natural leather grain is embossed using heat and pressure.